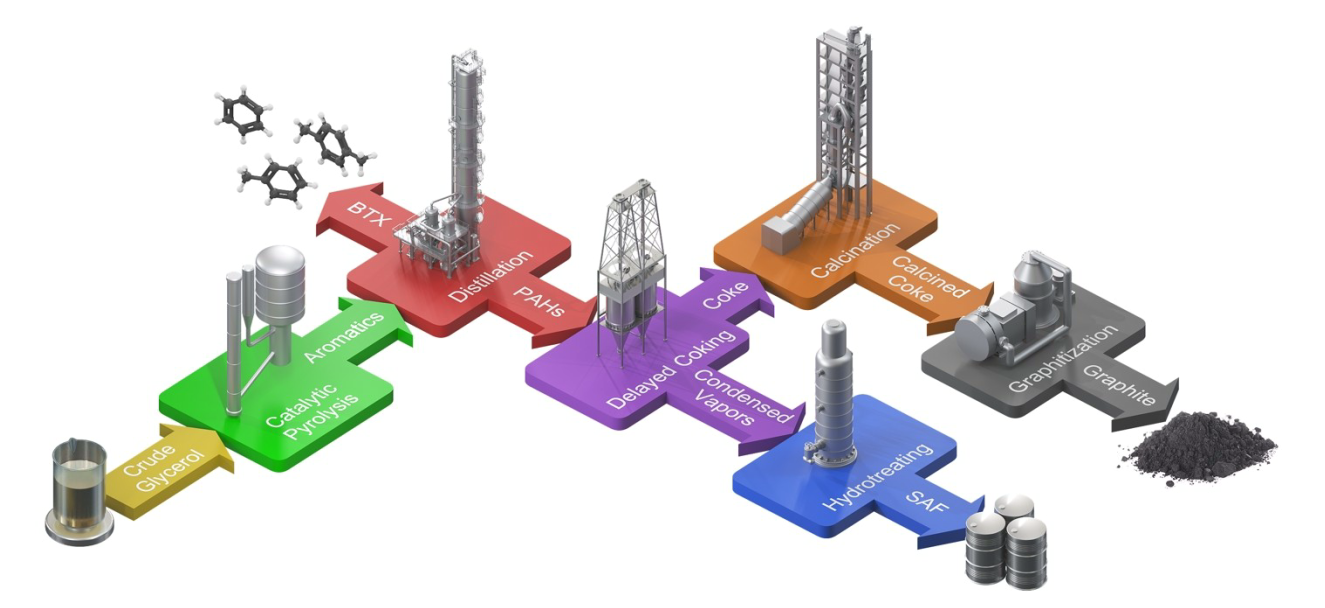

Sustainable Graphite and Jet from crude glycerol

BioBTX, a pioneering developer of renewable aromatics technology in the Netherlands, has

together with NC State University, NREL and BIRLA Carbon found a novel production route for SAF

and synthetic graphite. The novel production route explores the valorization of poly aromatic

hydrocarbons (PAH), produced out of crude glycerol via the BioBTX ICCP technology, into SAF and

synthetic graphite. The resulting bio-graphite exhibits excellent performance in lithium-ion battery

configurations.

By converting plastic waste and biomass into renewable aromatics, BioBTX is spearheading the

creation of a circular chemical industry, significantly reducing carbon emissions and reliance on fossil

fuels. Aromatics, essential for producing every-day products like insulating foams, coatings, PET

bottles, batteries, and pharmaceuticals, will now have a sustainable alternative to fossil-based

sources, presenting a major opportunity for circular business models.

The presented study explores a novel valorization pathway for PAH-rich aromatic oil, by transforming

them into battery-grade graphite and sustainable aviation fuel. The research was performed together

with North Carolina State University, the National Renewable Energy Laboratory (NREL), Birla Carbon

and BioBTX. Through the upcycling of the PAH-fraction into products for high value applications, not

only the circularity level of the plastic waste and biomass recycling increases, also the strategic

dependence of graphite can be decreased.

Ton Vries, CEO of BioBTX, says: “We are excited about this novel production process and additional

use of the aromatics. This not only increases the overall application of our aromatic oil, but can also

significantly contribute to achieving a circular economy. We are looking forward to explore the next

steps for realizing a circular graphite value chain.